in the present aggressive industrial landscape, suppliers face the twin problem of bettering effectiveness when meeting stricter environmental restrictions and growing purchaser desire for sustainability. classic cooling techniques, relying on open techniques, air-cooling, or chemical-primarily based coolants, are beneath scrutiny for his or her environmental effect and contamination pitfalls. the necessity for cleaner, much more responsible generation is driving the adoption of modern cooling options that produce productive temperature Regulate while aiming for zero emissions and contamination. Flaker equipment suppliers are leading this shift, featuring Highly developed solutions for industries necessitating exact cooling and solidification, such as chemical compounds, resins, waxes, and food items-quality things. obtaining cleaner production consists of rethinking each stage of manufacturing, with cooling enjoying a vital part. productive methods need to tackle air top quality, h2o utilization, product or service security, worker safety, and environmental impression. Enable’s examine how Highly developed cooling systems, which include improvements from best flaker device suppliers, are turning this eyesight into fact.

Table of contents:

Breathing simple: The Power of Zero Air Emissions

Pristine Waters: shut-Loop Cooling and Zero Wastewater Discharge

product or service Integrity certain: The Zero Cross-Contamination assure

Fostering a cleanse and Harmless Doing the job ecosystem

Hygienic structure & Effortless upkeep: The Efficiency Equation

Navigating Environmental Compliance and Bolstering ESG Commitments

Choosing Your spouse in clean up Cooling

respiration Easy: The Power of Zero Air Emissions

a major problem with a lot of regular industrial cooling procedures would be the emission of destructive airborne substances. These can include risky natural Compounds (VOCs), noxious fumes, steam, and also greenhouse gases like carbon dioxide, specifically if combustion is associated with any linked heating or Vitality technology for cooling. this sort of emissions not simply add to atmospheric pollution and also degrade the air good quality in and throughout the output facility.

modern-day, clean up cooling methods are engineered to do away with these problems. By design and style, systems like Superior steel belt coolers function without the will need for direct air cooling of your merchandise or substantial air heating mechanisms. This inherently signifies:

No VOCs or Fumes: merchandise are cooled indirectly, normally on a sealed surface area, protecting against the release of solution-precise VOCs or system-relevant fumes into your atmosphere. This is particularly very important in chemical processing where VOCs might be equally an environmental hazard and a health and fitness chance.

Reduced Carbon Footprint: getting rid of direct CO2 emissions linked to older cooling or associated energy-intensive air managing devices contributes straight to an organization’s carbon reduction aims.

Improved Plant Air Quality: The absence of these emissions translates to some noticeably more healthy working natural environment for workers, cutting down the need for in depth air filtration systems or personal protecting devices related to air quality.

Regulatory Compliance: Conference and exceeding stringent environmental procedures, for example All those set through the EPA in the United States or access in Europe, results in being considerably more achievable. This proactive strategy minimizes the chance of penalties and enhances a company's popularity as an environmentally accountable operator.

methods that obtain zero air emissions are not just an environmental upgrade; they characterize a essential advancement in operational protection and long-phrase sustainability.

Pristine Waters: shut-Loop Cooling and Zero Wastewater Discharge

h2o is really a treasured source, and its use in industrial cooling has traditionally been An important supply of consumption and potential air pollution. open up-loop cooling units typically discharge heated or chemically taken care of h2o, even though even some closed-loop devices can contain coolants that pose disposal issues.

The hallmark of A very cleanse cooling Remedy lies in its method of the cooling medium, normally drinking water. Highly developed units winner the idea of closed-circuit water cooling:

absolutely Enclosed drinking water methods: The cooling h2o circulates in just a completely sealed loop. It passes beneath the cooling surface (like a steel belt), absorbs warmth from the solution indirectly, which is then re-cooled and recirculated. there is absolutely no direct connection with the solution and no discharge to external water bodies or municipal sewer units.

Reusable Coolant: as the drinking water continues to be contained and uncontaminated via the solution, it could be reused indefinitely with minimum major-up required to compensate for slight evaporation inside the cooling device by itself (not from the method). This radically lowers All round h2o usage, a essential Think about drinking water-scarce regions or for providers aiming for h2o stewardship.

Elimination of Chemical procedure and Disposal charges: Because the cooling drinking water will not blend Along with the merchandise or develop into seriously fouled, the necessity for aggressive chemical remedies (biocides, anti-scaling brokers) is appreciably lowered or eradicated. This, in turn, removes the sizeable costs and environmental pitfalls related to treating and disposing of chemical-laden wastewater.

This approach don't just conserves drinking water and shields aquatic ecosystems but also provides major operational cost discounts.

merchandise Integrity certain: The Zero Cross-Contamination Promise

For industries like food items processing, prescription drugs, and fine chemical compounds, product purity is non-negotiable. Any interaction in between the product as well as cooling medium, or residues from former batches, can cause contamination, batch rejection, and severe reputational damage.

thoroughly clean cooling technologies, Specially People using indirect cooling surfaces like chrome steel belts, are designed with solution integrity to be a paramount problem:

finish merchandise-Coolant Isolation: The product is solidified on a person facet of the sanitary, impervious barrier (the metal belt), although the cooling medium (water) circulates on another. This physical separation guarantees there is absolutely no possibility of the cooling h2o or any contaminants it would theoretically have (although not likely inside of a clear, shut program) coming into contact with the merchandise. The merchandise's chemical composition, purity, and features stay unchanged.

perfect for delicate Industries: This tends to make these kinds of methods extremely properly-fitted to applications exactly where even trace contamination is unacceptable. food items-grade products and solutions, Energetic pharmaceutical elements (APIs), and superior-purity specialty chemical substances can be processed with self confidence.

Compliance with Stringent criteria: The design rules align beautifully with the requirements of Good production tactics (GMP), Hazard Examination and important Command details (HACCP), and FDA polices, which all emphasize protecting against contamination and making sure product basic safety and high-quality.

This warranty of contamination-cost-free processing is a cornerstone of recent, substantial-benefit producing.

Fostering a thoroughly clean and Harmless Functioning ecosystem

The impact of industrial procedures about the rapid Operating environment is really a critical facet of operational well being and protection, as well as worker morale and efficiency. common cooling units can from time to time contribute to messy, noisy, or harmful plant floors.

clean up cooling alternatives inherently market an improved office:

Dust-free of charge and Vapor-no cost Operation: as the item is typically managed in the molten state and solidified with a contained surface, and also the cooling is oblique and enclosed, the era of dust or vapors affiliated with the cooling procedure by itself is just about eradicated. This contributes to cleaner air and surfaces throughout the workshop.

Increased employee basic safety: A cleaner surroundings lessens slip hazards from spills or condensed vapors. The shortage of airborne irritants or fumes indicates personnel can generally get the job done with no need specialised respiratory security or in depth dust-Management equipment, increasing comfort and ease and lessening the potential risk of occupational health issues.

Simplified Environmental administration Audits: amenities using these types of cleanse systems frequently obtain it simpler to move and maintain certifications like ISO 14001 for environmental management programs, as important pitfalls connected with emissions and squander are inherently created out with the cooling method.

Quieter Procedure: contemporary belt-based devices will often be quieter than older, extra mechanically intensive cooling apparatus, contributing to the fewer annoying plus more focused get the job done environment.

A clean, vapor-cost-free, and dust-totally free factory is not only aesthetically pleasing; it's a safer, much healthier, and even more effective spot to get the job done.

Hygienic layout & Effortless upkeep: The Efficiency Equation

routine maintenance and cleaning are unavoidable elements of any industrial Procedure. having said that, the design in the machines can drastically impression some time, work, and cost involved. methods with intricate geometries, tough-to-get to parts, or People prone to leakage and residue build-up could become a servicing burden.

Clean cooling remedies usually feature hygienic style and design ideas:

Minimized Residue and Leakage: The enclosed character of the cooling medium and The graceful, non-porous surfaces useful for product or service Get hold of (like stainless steel belts in a flaker machine) suggest minimum prospects for product or service residue to accumulate get more info in hidden places or for cooling medium to leak.

effortless-to-clean up Surfaces: Stainless steel, a typical substance in higher-top quality cooling belts, is renowned for its cleanability and resistance to corrosion and microbial development. easy surfaces without having crevices stop substance Create-up and make wipe-down or wash-down treatments quick and effective.

Reduced routine maintenance Downtime and expenses: less difficult cleaning interprets on to less downtime. On top of that, the robustness of properly-designed methods, with less factors of possible failure linked to emissions or effluent administration, contributes to decreased All round maintenance charges and increased operational uptime.

Suitability for High-Hygiene programs: These features are indispensable in sectors like infant system manufacturing or perhaps the production of pharmaceutical syrups, in which the highest amounts of hygiene are mandated to stop any kind of contamination. A hygienic flaker or cooler style is essential.

buying products that is a snap to wash and keep is really an expense in very long-expression operational efficiency and solution top quality.

Navigating Environmental Compliance and Bolstering ESG Commitments

The regulatory landscape is continually evolving, with a transparent trajectory toward stricter environmental controls. over and above mere compliance, there is a expanding expectation for firms to reveal strong ecosystem, Social, and Governance (ESG) performance.

thoroughly clean cooling systems give a immediate pathway to reaching these goals:

Meeting and Exceeding Environmental Regulations: By inherently removing air emissions and wastewater discharge, these devices aid corporations effortlessly satisfy latest environmental legislation and stay ahead of future, far more stringent restrictions, minimizing the chance of fines or operational disruptions.

Tangible aid for ESG Reporting: The quantifiable Rewards – lowered h2o use, lessen carbon footprint, elimination of harmful squander – provide concrete info details for the "natural environment" pillar of ESG studies. This demonstrates a motivation to sustainability that is certainly ever more valued by buyers, buyers, and stakeholders.

Improved brand name Image and Market accessibility: A demonstrable determination to clean production procedures enhances a firm's manufacturer reputation. It appeals to environmentally conscious customers and will be a major differentiator, significantly when concentrating on Intercontinental markets with large environmental benchmarks. This positions the company as being a liable, ahead-pondering chief.

deciding upon industrial cooling options that align with environmental most effective tactics is no more a niche thought but a strategic essential for sustainable enterprise success.

selecting Your Partner in clean up Cooling

The changeover to zero-emission, zero-contamination cooling demands not just the appropriate technology, and also the proper experience. Partnering with a highly skilled flaker machine supplier or perhaps a service provider of comprehensive industrial cooling methods is essential. they're able to help evaluate specific procedure requires, advocate the optimal system configuration, and ensure seamless integration into existing creation lines. The purpose is to locate a solution that not only satisfies today's purity and environmental criteria but is usually strong and adaptable to the issues of tomorrow.

eventually, the pursuit of "Zero Emissions, Zero Contamination" in industrial cooling is about developing a acquire-gain scenario: shielding the planet, guaranteeing products integrity, safeguarding staff, and creating a far more resilient and rewarding business. Companies like CONSOL, with their advanced steel belt units, exemplify this motivation, providing technologies that happen to be built from the ground up for cleanse, efficient, and sustainable generation, encouraging industries throughout the world move to a cleaner upcoming.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Rider Strong Then & Now!

Rider Strong Then & Now! Josh Saviano Then & Now!

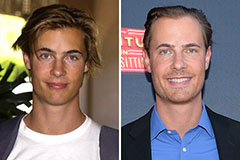

Josh Saviano Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!